Product innovation

By collaborating with our industry and customers, we continue to define what’s next.

Every year, Lam strives to enable semiconductor breakthroughs that may have seemed impossible the year before. Through experimentation, collaboration, and rigorous testing, we continue to do what’s never been done. Today, advanced microchips shape everything from how we communicate to how we work and drive. The potential for future innovation is limitless, but we don’t plan to realize it alone. Instead, we’re prioritizing open communication and strategic investments in research and development (R&D). By embracing diverse perspectives, we can unlock a faster, smarter, and more sustainable world.

In 2022, we sponsored and participated in numerous industry and university events to collectively address the semiconductor industry’s most pressing challenges. One highlight was our Tech Symposium, themed “Engineering a Greener Fab.” Internally, we focused on developing smarter, more efficient products and processes to measure and reduce the greenhouse gas (GHG) emissions footprint of our tools. These efforts support sustainability in our industry.

Product innovation1

Product innovation1

| Goal | Status | Progress |

|---|---|---|

| Goal: 83% of customers measured by emissions set science-based targets (SBTs)2 |

Status:

|

Progress:

|

2022 highlights

Released three new products: Argos®, Prevos™, and Selis®

Began establishing a baseline to measure Lam’s product-based energy usage and emissions

Invested over

$1.6 billion in R&D3

Opened new R&D labs

in India and South Korea

- Unless stated otherwise, we aim to complete each of our ESG goals by 2025.

- Previously, this goal targeted SBTs for 83% of customers measured by revenue by 2025. Lam updated this goal in 2022 per the SBTi verification and approval process.

- Based on Lam’s 2022 fiscal year.

Creating our most efficient and sustainable

generation of products

It starts by sparking sustainable innovations.

- Investing in R&D—including over $1.6 billion in 20221

- Listening to our customers and imagining new ways to meet their needs

- Breaking down research silos and bringing experts together to explore big ideas

Understanding our product impact and opportunities is key.

- Using Equipment Intelligence® sensors to measure the GHG emissions and energy usage of our products

- Incorporating Design for Environment (DfE) principles and designing for the entire product lifecycle

- Embracing smart solutions to accelerate Industry 4.0

The result: Breakthrough solutions that enhance performance, precision, and yield, including:

- Sense.i®: A smart solution that enables customers to reduce their energy and material and achieve a smaller fab footprint

- Argos®, Prevos™, and Selis®: Products that enable ultra-high selectivity and precision to facilitate the next generation of 3D devices

- Coronus®: A bevel clean system that improves yield by up to 2% per wafer

- Based on Lam’s 2022 fiscal year.

Bringing our Tech Vision to life

Technology moves fast—and it’s not enough to just keep pace. At Lam, we’re determined to lead our industry into a future that works better for us all. Rather than taking a single-minded approach, we focus on bringing together our industry’s brightest minds. Together, we’re asking big questions, addressing persistent challenges, and realizing new opportunities for what semiconductors can do.

Building an innovative workforce

Our work to accelerate large-scale innovation begins by inspiring Lam’s teams. Each year, our Office of the Chief Technology Officer organizes a variety of collaborative and innovation-focused internal events. We also make a point to highlight Lam employees who are driving innovation and providing opportunities to share their knowledge with others.

In 2022, we continued our Celebrating Innovation campaign for the second year to highlight stories of innovation by employees in technical and non-technical roles (look for highlights in our Innovation Spotlights throughout this report). Lam’s leaders also engaged our global technological community through several sessions focused on our Core Values. Through our Seminar Series, we invited our engineering community to share their work and insights with their peers. Additionally, our Innovation Speaker and Book Series brought the outside world in to educate and inspire Lam employees. Topics featured during our 2022 Innovation Speaker Series include: the intersection of innovation and ESG, how to innovate inside bureaucracies, developing a culture of innovation, and innovations in additive manufacturining, among others.

Driving research-backed breakthroughs

As chip technology becomes radically small and almost inconceivably precise, the challenges we face become greater and more complex. We support academic research that provides insights into these challenges and opportunities for our industry to advance. By collaborating with leading universities around the world, we boost innovation and fuel our talent pipeline.

Learn more about

how we’re bringing

our Tech Vision to life

Opening the doors to two new global hubs of R&D

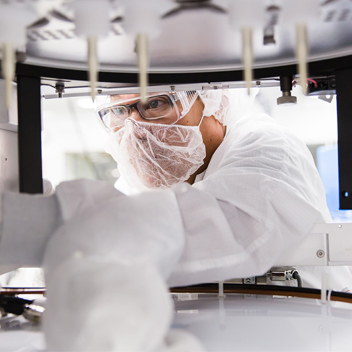

One way we accelerate learning and development cycles is through our investments in semiconductor R&D. In 2022, we opened two advanced facilities in South Korea and India.

Located in the heart of South Korea’s K-semiconductor cluster, the Korea Technology Center enables Lam engineers and customers to work side-by-side. Together, they can qualify new devices, processes, and yield improvements—allowing for fewer and faster development cycles. The new location also lends itself to closer relationships with local suppliers, universities, and research institutions, and has the added environmental benefit of less travel.

Our India Center for Engineering specializes in the R&D, engineering, and testing of wafer fabrication hardware and software used to create next-generation memory and logic devices. The new facility doubles Lam’s footprint in India and supports shorter development cycles by enabling engineers to design, test, and validate new deposition and etch technologies on site.

I see vast potential in the ability of our engineers to have hands-on access to Lam’s tools at the India Center for Engineering. This access will have a transformative impact on both the speed and the quality of the engineering solutions that are being developed there.”

Sesha Varadarajan

senior vice president, Global Products Group at Lam

How we’re unlocking research-backed breakthroughs

Unlock Ideas

provides awards to support the testing of novel ideas proposed by Lam’s global technical community in collaboration with university faculty. In 2022, the program sought proposals in categories including sustainability for the second year.

University Collaboration Showcase

brings Lam employees together to share results from our university research collaborations and Unlock Ideas projects. We hosted the event virtually for the third year in 2022.

Elevate Ideas

provides additional funding and support to take successful Unlock Ideas projects to the next level. After piloting the program in 2021 with two awards, we awarded two new winners in 2022.

Bringing experts together to engineer a greener fab

It’s not easy to change processes that take place on an atomic scale, but for the sake of our industry and planet, there’s got to be a greener way. That was the focus of Lam’s 2022 Technical Symposium, themed “Engineering a Greener Fab.”

The symposium is Lam’s premiere forum for joint academic and industry cooperation. The 2022 event took place at the University of California, Berkeley, with participants joining in person for the first time since 2019.

Experts used the forum to share and discover leading-edge technologies aimed at advancing environmental sustainability for semiconductor fabrication. Highlights included faculty presentations, panels, student posters, and keynotes from our customers Intel and Micron.

The key to innovating is bringing together diverse groups of people and going outside our own little world.”

Rick Gottscho

executive vice president, strategic advisor to the CEO, and former chief technology officer at Lam

Supporting the next generation of semiconductor innovators with Lam Capital

Sometimes, you’ve got to disrupt the system to move it in a new direction. In that regard, Lam Capital invests in innovative companies that are addressing today’s most high-impact problems.

In conjunction with the Tech Symposium, we hosted our second-annual Lam Capital Venture Competition in 2022. During the event, select startups pitched sustainable innovations to a panel of venture capital judges. Proposed solutions ranged from wastewater treatment to microfabs to energy-saving strategies. The winning startup, XLight, pitched an energy-efficient technology for photolithography. The prize: a $250,000 investment funded by Lam Capital.

2022 Tech Symposium by the numbers

11

universities

represented

11

finalist startups

presented

6

customer keynotes and

faculty presentations

6

venture capital judges, plus

judges from Lam Capital

$250 thousand

investment to the winning team by Lam Capital

Developing sustainable solutions

We are driven to accelerate a net zero transition and a future where our company and customers can achieve more while using less. In that pursuit, one of the most impactful steps we can take is to track and reduce our product-based emissions. This will give Lam an edge in providing the solutions customers need to reduce their environmental impact while meeting increasing demands.

As of 2022, emissions generated from the energy use of our products represent 55% of our total GHG emissions. To reduce the emissions output of our products, we’re optimizing solutions that are smarter and more efficient. In doing so, we’re proving that it’s possible to increase productivity while reducing the use of raw materials, energy, and space.

Accelerating Industry 4.0

A new phase of the industrial revolution is beginning—known widely as Industry 4.0. It’s an era defined by automation, machine learning, interconnectivity, and real-time data. Our Equipment Intelligence® solutions combine these elements with Lam’s equipment and process expertise. By enabling faster learning cycles, these solutions help customers enhance productivity, efficiency, and performance while minimizing waste.

For example, Lam’s Net Zero Product Working Group uses Equipment Intelligence® sensors to monitor and report the energy and resource consumption of our lab tools. In 2022, the group worked toward establishing baseline data for our tools’ energy consumption and GHG footprint. This will help Lam address our product-based emissions, while supporting our customers’ sustainability goals. The working group’s vision is to connect this data to specific fab processes, enabling customers to optimize resource planning and reduce their energy usage, GHG emissions, and costs. We also made progress on product sustainability by:

- Implementing throughput and uptime improvements, which improve the efficiency of tool operations by 4% and yield with station matching by 60%.

- Releasing new ECO Mode features for 2300 and Sense.i® etch tools, which save up to 30% peripheral energy in idle mode and result in faster tool time recovery.

- Increasing RF generation efficiency on our Vantex tool, which reduces the energy consumed per RF subcomponent by 10%.

Incorporating DfE principles

DfE principles guide us to develop products with their full lifecycle in mind. In doing so, we’re finding ways to reduce the environmental impact of our products while maintaining or improving quality and value. In 2022, our working group continued to incorporate these principles into the product design process.

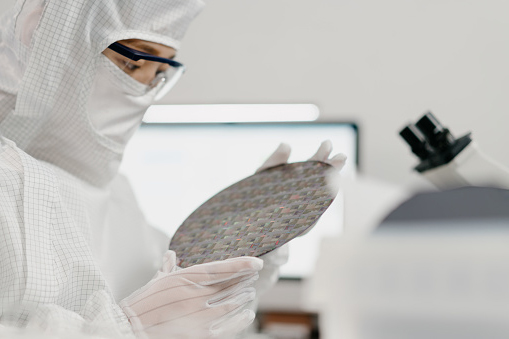

Three new products that are accelerating

three-dimensional (3D) scaling

Typically, companies talk about scaling in terms of expansion. In semiconductor manufacturing, it often means the opposite. One of our industry’s pressing challenges is to continuously scale the tiny devices in chips to make chips that are smaller, denser, and more powerful. This is driving many semiconductor manufacturers to move away from planar structures in favor of complex, 3D versions.

Lam’s etch and deposition tools are at the forefront of this innovation, and in 2022, we announced three new precision selective etch innovations: Our new Argos®, Prevos™, and Selis® products are designed to complement and extend Lam’s industry-leading etch solutions portfolio. These breakthrough products are enabling chipmakers to etch and modify films with ultra-high selectivity and precision to achieve the most advanced integrated circuit performance capabilities and accelerate 3D scaling.

Giving our customers

a market edge

When they ask, we deliver. That’s how we build our customers’ trust. And what many of them want are faster, more efficient, and sustainable chipmaking solutions. Our customers are global technology leaders, and we take pride in supporting their success. Through close collaboration, we strive to exceed their expectations and continuously anticipate their long-term needs.

Our Customer Support Business Group (CSBG) supports Lam’s customers across the equipment lifecycle. From solutions that increase system uptime to offerings that extend the product lifecycle, the group’s goal is to help customers optimize quality and cost, with the added benefit of reducing their environmental impact.

CSBG’s strategy for providing best-in-class customer support:

Lam’s installed base included approximately

84,000

chambers at the end of 2022.

Customized service and software solutions that enhance productivity throughout the product lifecycle

High-quality, low-defect consumable and non-consumable spare parts designed to increase circularity while balancing performance, availability, and cost

Technology and productivity upgrades that increase productivity, reliability, and efficiency and extend product lifecycle

Reliant systems, including new and refurbished equipment, that extend product lifecycles, increase production capacity, and decrease waste

Technical training, including software and hardware courses, to develop customers’ knowledge and technical expertise

Innovation spotlight

Simulating complex processes to

get real results

Lam engineers have a knack for getting to the bottom of vexing customer challenges. Yet wafer-based experiments require an investment in resources and time. Realizing this, several have turned to our powerful SEMulator3D software to create renderings, simulate fabrication processes, and calculate the physical properties of nanostructures without ever stepping into a lab.

Among them is Peng Fei Lyu (left), a process engineer who facilitated a special interest group to receive training on the software at Lam China. After learning the software, the team used it to identify the root cause of an issue in a customer’s etch process—cutting a task that would have taken approximately 10 wafers and two weeks in a lab down to about an hour.

Another member of the group, process engineer Tian Hao Zhang (right), used the software to help a customer determine their ideal etching approach. In doing so, he and his colleagues cut the experimentation time down from 10 weeks to four while using a third of the wafers required for traditional testing. By helping engineers deliver rapid results while reducing material waste and costs, the software is helping Lam build value for our company and customers.

Products that support a circular economy

When great products go further, we all win. In addition to new systems, CSBG provides refurbished tools, previous generation tools, and equipment upgrades. These options deliver great customer value while avoiding the environmental impacts of manufacturing new tools and sending existing equipment to landfills. Our spares offerings include the reuse of high-value spare parts such as electrostatic chucks, RF hardware, and showerheads through a variety of re-cleaning, repair, refurbishment, and re-coating services. Learn more about our spares offerings.

How our CSBG offerings make a difference:

~$400M worth of annual materials savings enabled by re-cleaning services

~$150M worth of annual materials savings enabled by repair & refurbishment services

20% of Etch installations used upgrades or tools with refurbished components in 2022

33% of electrostatic chucks (ESCs) shipped in 2022 were refurbished, representing a 70%+ increase since 2019

~8kg aluminum reused in each refurbished ESC baseplate, representing 30 metric tons (MT) reused in 2022

~5kg hazardous residue avoided by each refurbished ESC baseplate, representing 18 MT avoided in 2022

Delivering safe, high-quality products

Our cross-functional Quality Leadership team oversees our design teams to ensure the safety and quality of every product they create. We take a systematic approach to continuously improve our products and strive to quickly address any adjustments that need to be made. Lam is also certified under ISO 9001, an international standard that provides a framework for an effective quality management system.

Learn more about

our commitment

to product safety

Earning recognition as an outstanding supplier

Lam has proudly achieved the top honor within the Intel global supply chain: The Intel EPIC Outstanding Supplier Award. Of the thousands of suppliers Intel works with every day, Lam was one of only six companies to win this award for 2022.

In a truly unique and volatile supply chain environment, Lam has earned Intel’s top supplier award through its steadfast commitment to safety, quality, diversity and inclusion, continuous innovation, and its close partnership with Intel toward operational excellence results.”

Keyvan Esfarjani

executive vice president and

global chief operations officer at Intel