制造无暇的

薄膜

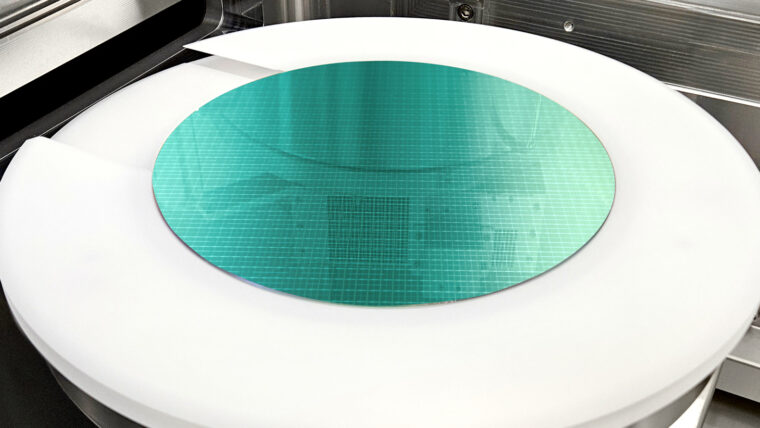

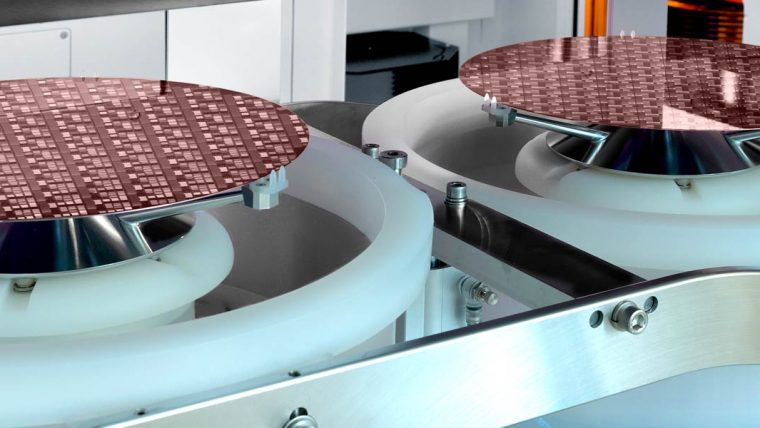

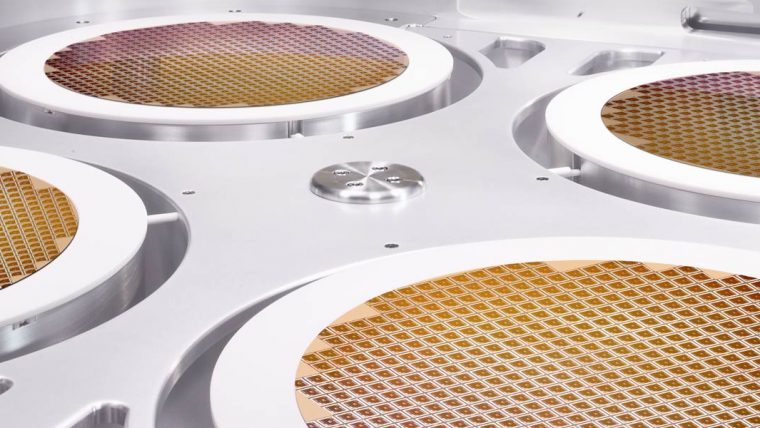

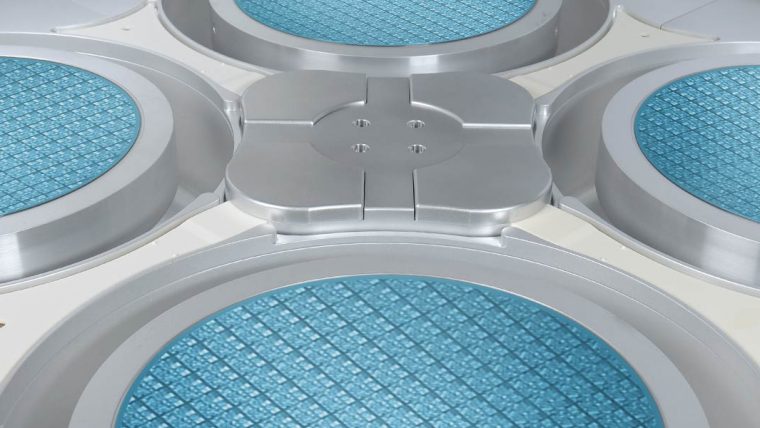

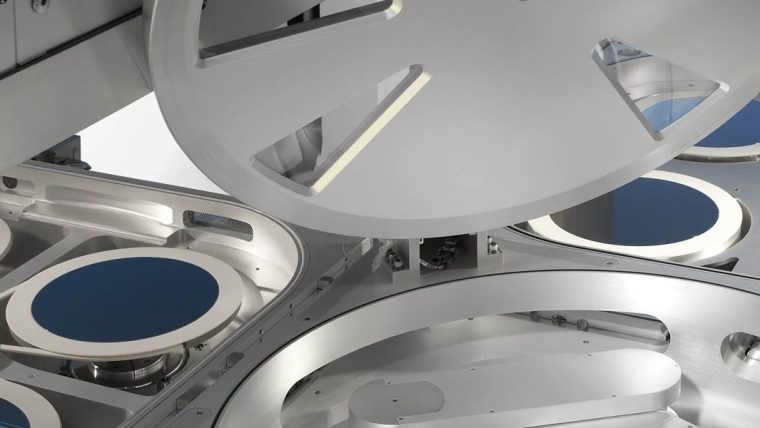

沉积工艺可形成用于制造半导体器件的电介质(绝缘)和金属(导电)材料层。 根据材料和结构的类型,会采用不同的技术。 电化学沉积(ECD)可生成连接集成电路中器件的铜“布线”(互连)。 铜和其他金属的金属电镀也用于硅通孔和晶圆级封装应用。 利用化学气相沉积(CVD)和原子层沉积(ALD)技术,每次只需添加几层原子,就能精确地制造出微小的钨连接器和薄壁层。 使用等离子体增强化学气相沉积(PECVD)、高密度等离子体化学气相沉积(HDP-CVD)和原子层沉积(ALD),以形成隔离和保护所有这些电气结构的关键绝缘层。使用脉冲激光沉积(PLD)技术可实现高性能压电层。PLD 是一种物理气相沉积方法,它使用高脉冲能量激光束来轰击材料,产生沉积蒸汽,并将其凝结在不同的基底上。

对于所涉及的众多材料和高要求特征,泛林集团的薄膜沉积产品可为各种具有挑战性的器件应用提供所需的精度、性能和灵活性。

沉积

我们的产品相关博客文章

-

Lam’s Laser Focus on the Future of Chip Manufacturing

Mar 26, 2024Lam Research hopes to revolutionize microchip manufacturing with the launch of a new system: Prestis™. Why it matters: For the first time in semiconductor production, Lam is using lasers to deposit thin films and bringing pulsed laser deposition (PLD) to wafer-level mass production. Prestis is expected to be key in developing cutting-edge specialty technologies devices, such as RF (radio frequency) filters for 5G and Wi-Fi 6 and high-end MEMS (micro-electromechanical systems) microphones.

-

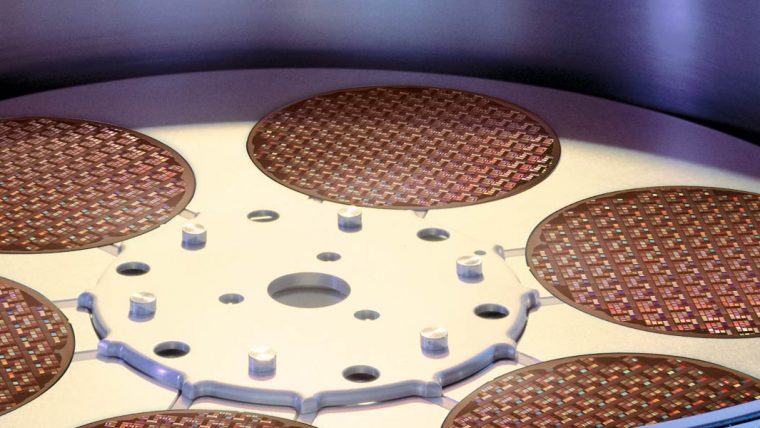

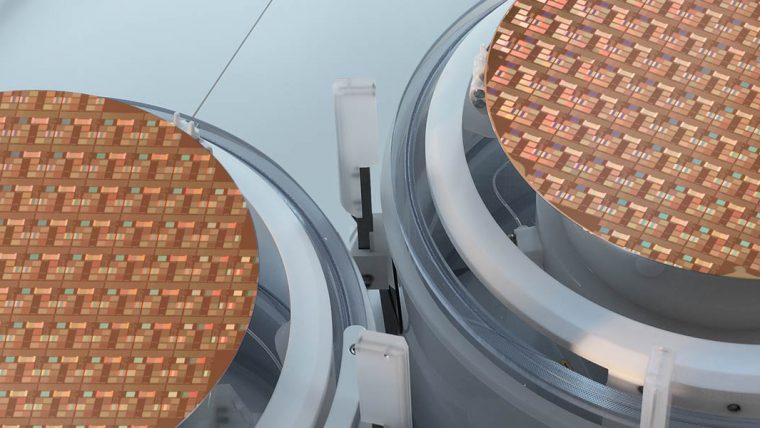

Introducing Coronus DX, World’s First Bevel Deposition Solution Optimized for 3D Chipmaking

Jun 20, 2023For more than 15 years, Lam’s Coronus® product family has been the leader in wafer bevel technology. Today we introduced the newest member of the family, Coronus DX. It’s the industry’s first bevel deposition solution optimized to tackle key manufacturing challenges in next-gen logic, 3D NAND and advanced packaging applications.